The PTL filter monitoring is especially developed for constant function monitoring of diesel particulate filter systems.

The electronical device measures the exhaust temperature as well as the back pressure ahead of the filter. To suit each vehicle type and effort, additional a measuring probe for recording the number of revolutions can be connected. By the default option the displaying of the operating states take place via a three-tone LED, which is installed in the cockpit of the vehicle or rather engine. Possible malfunctions as well as the load status of the particulate filter are able to be recognized immediately and can be eliminated by the driver if necessary.

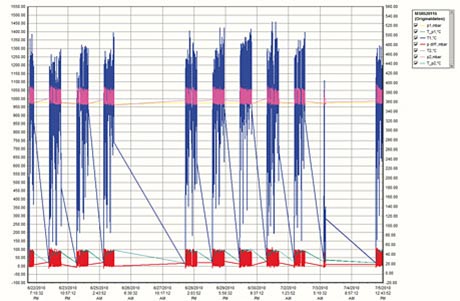

According to customer requests, the PTL filter monitoring is able to be equipped with further display screens. Under "Options" below, you can find closer details. As standard feature the device is equipped with an memory module which records all measured operating data (temperature, back pressure, revs, alarm indicator) in freely selectable intervals. The whole electronic is built-in an IP 65, aluminium die-cast housing, and therefore suitable for an assembly in the engine compartment or external undeveloped land.

If so, please call us or send us an email! Our competent team will be there to assist you throughout.