The »Active Wall-Flow HC-dosing« (AWF h) ) Particulate Filter System is a solution for vehicles and machinery that require low load profiles due to their areas of application and in which the exhaust temperatures repeatedly drop below the critical limits for purely passive regeneration. Depending on the vehicle or machinery application, the system automatically starts regeneration of the particulate filter when the counterpressure exceeds a freely programmable value. During regeneration, the diesel is injected into the exhaust gas, which increases the temperature in the filter to around 600 °C. At these temperatures, the carbon contained in the filtered particulate matter reacts with the residual oxygen in the exhaust. This allows regeneration to work independently from the vehicle/machinery application, effectively eliminating downtime.

This makes the AWF-h Particulate Filter the perfect technical solution for original equipment as well as for retrofitting of commercial vehicles, construction machinery, rail vehicles, ship engines and stationary engines with regularly occurring application-based phases in the lower load range.

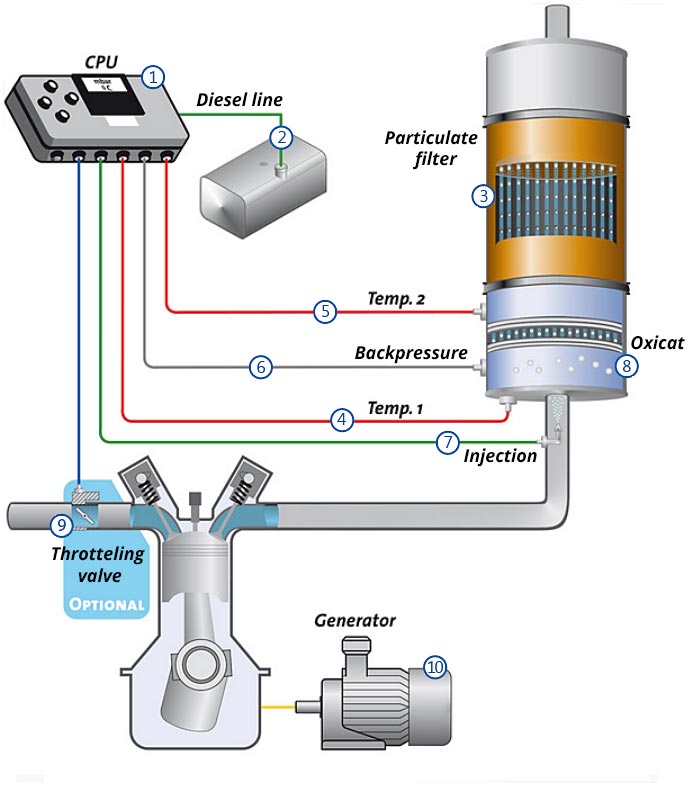

1 CPU

2 Diesel line

3 Diesel particulate filter

4 Temperature 1

5 Temperature 2

6 Backpressure

7 Injection

8 Oxidation catalyst

9 Throtteling valve (optional)

10 Generator

If so, please call us or send us an email! Our competent team will be there to assist you throughout.